Amazing Tips About How To Build An Absorption Chiller

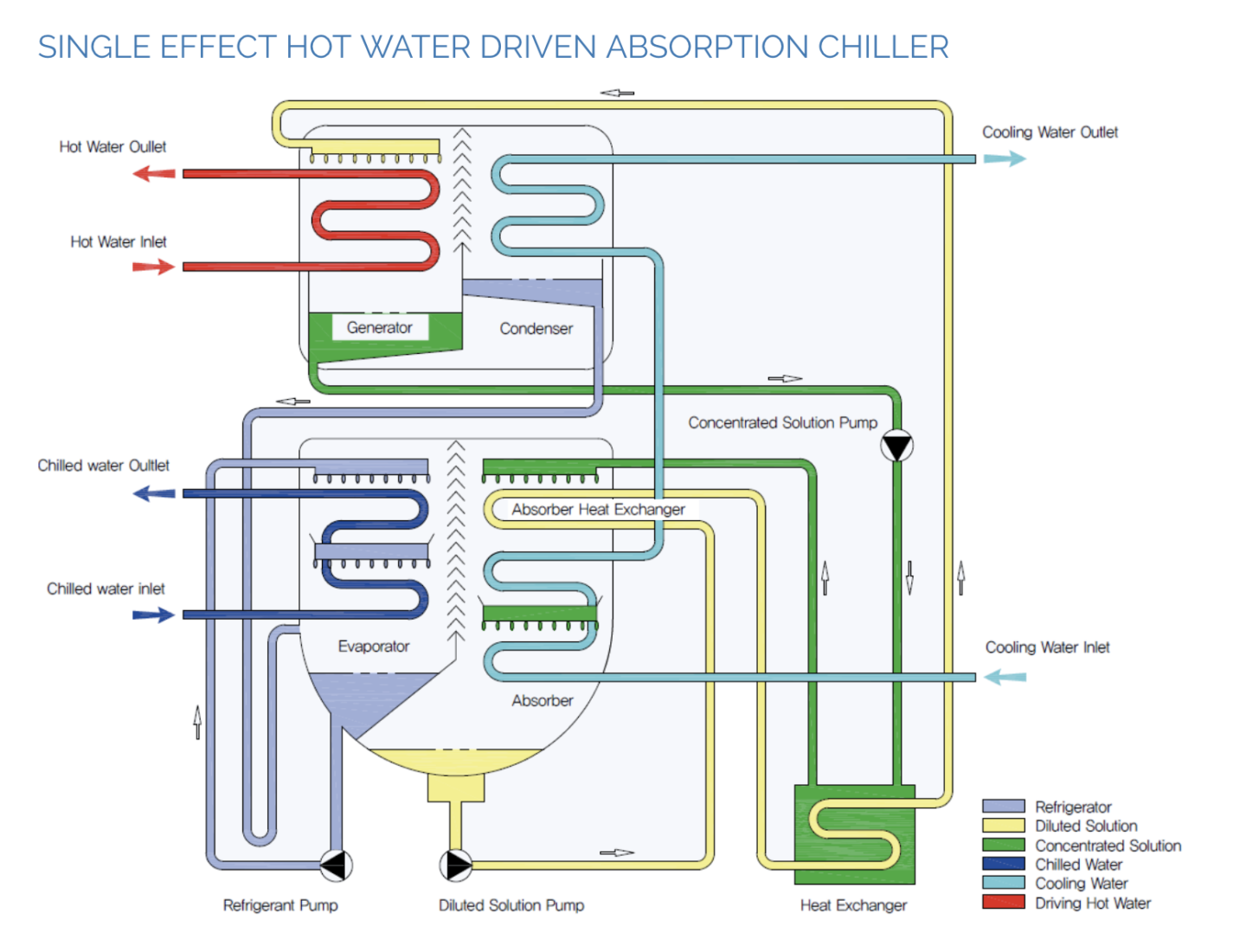

An absorption chiller is consisted of four main parts:

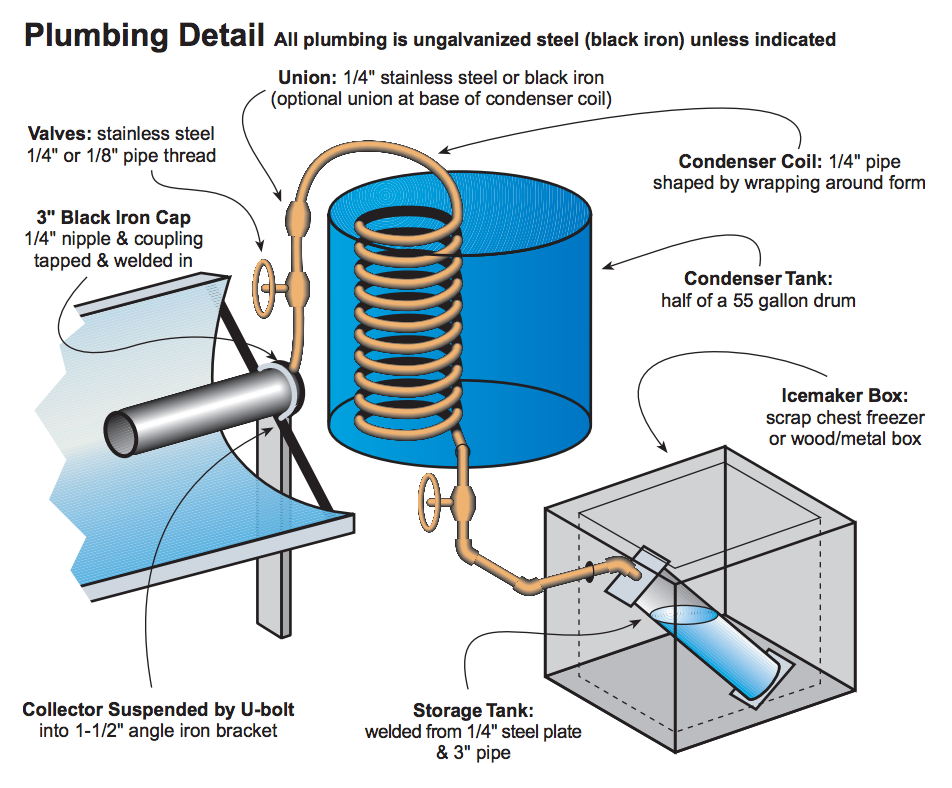

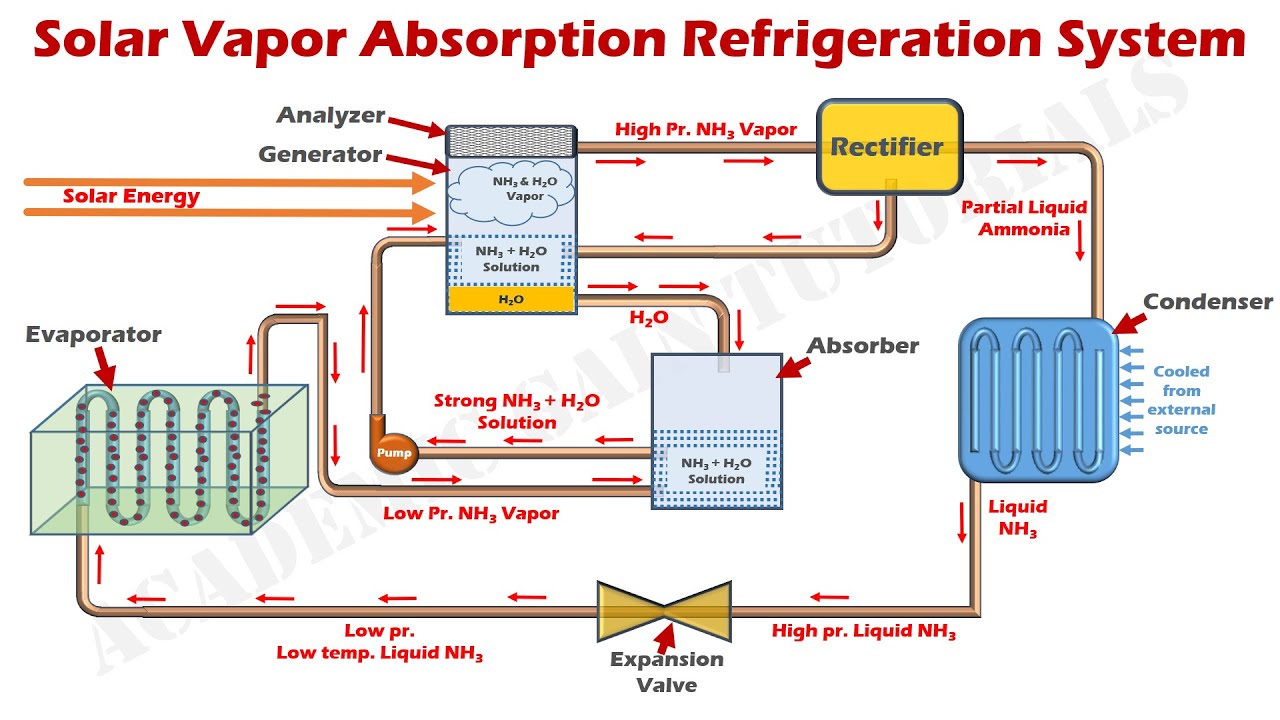

How to build an absorption chiller. There were various explanations of why this was “not a good idea”. Determine cooling load requirements and the cost of meeting. The principle behind an absorption process is to separate and recombine to fluids (refrigerant and absorbent) to create a cooling effect.

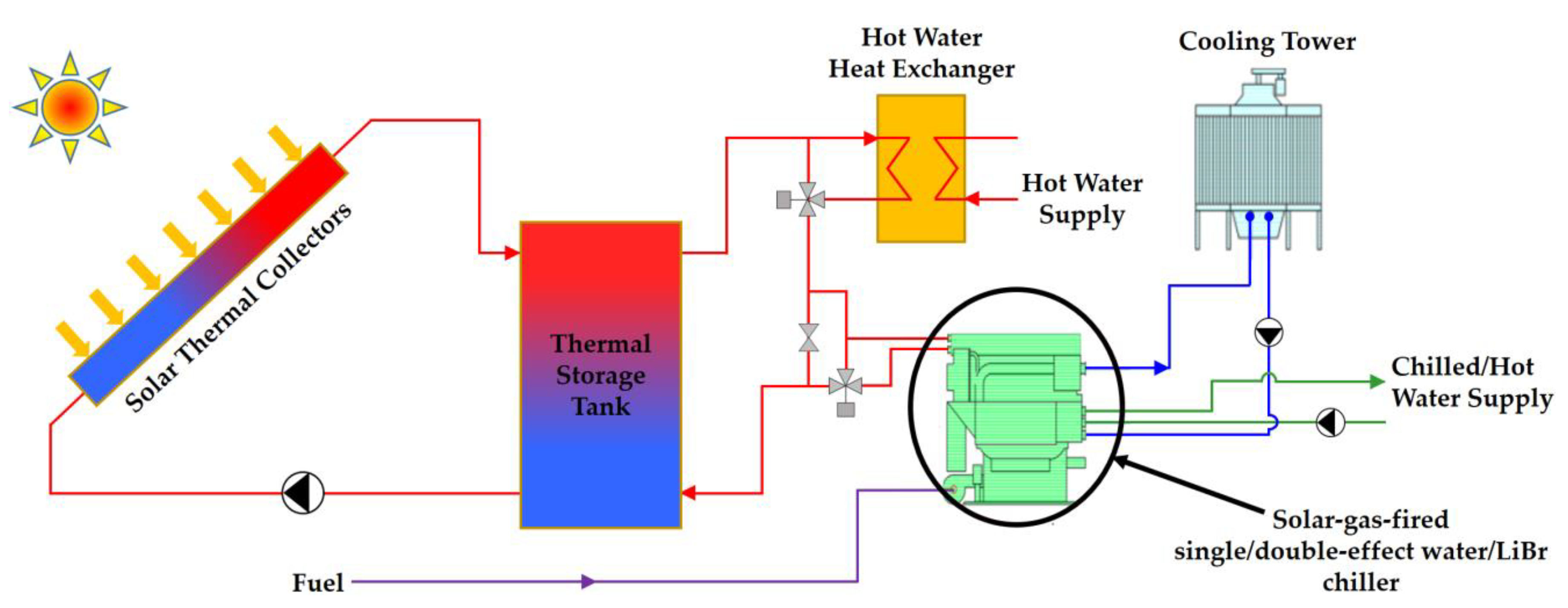

About press copyright contact us creators advertise developers terms privacy policy & safety how youtube works test new features press copyright contact us creators. Absorption water chillers make use of the absorption refrigeration cycle and do not use a mechanical compressor. This installation consists of two 415 kw reciprocating engine generators and an absorption chiller that produces 160 tons of 25°f.

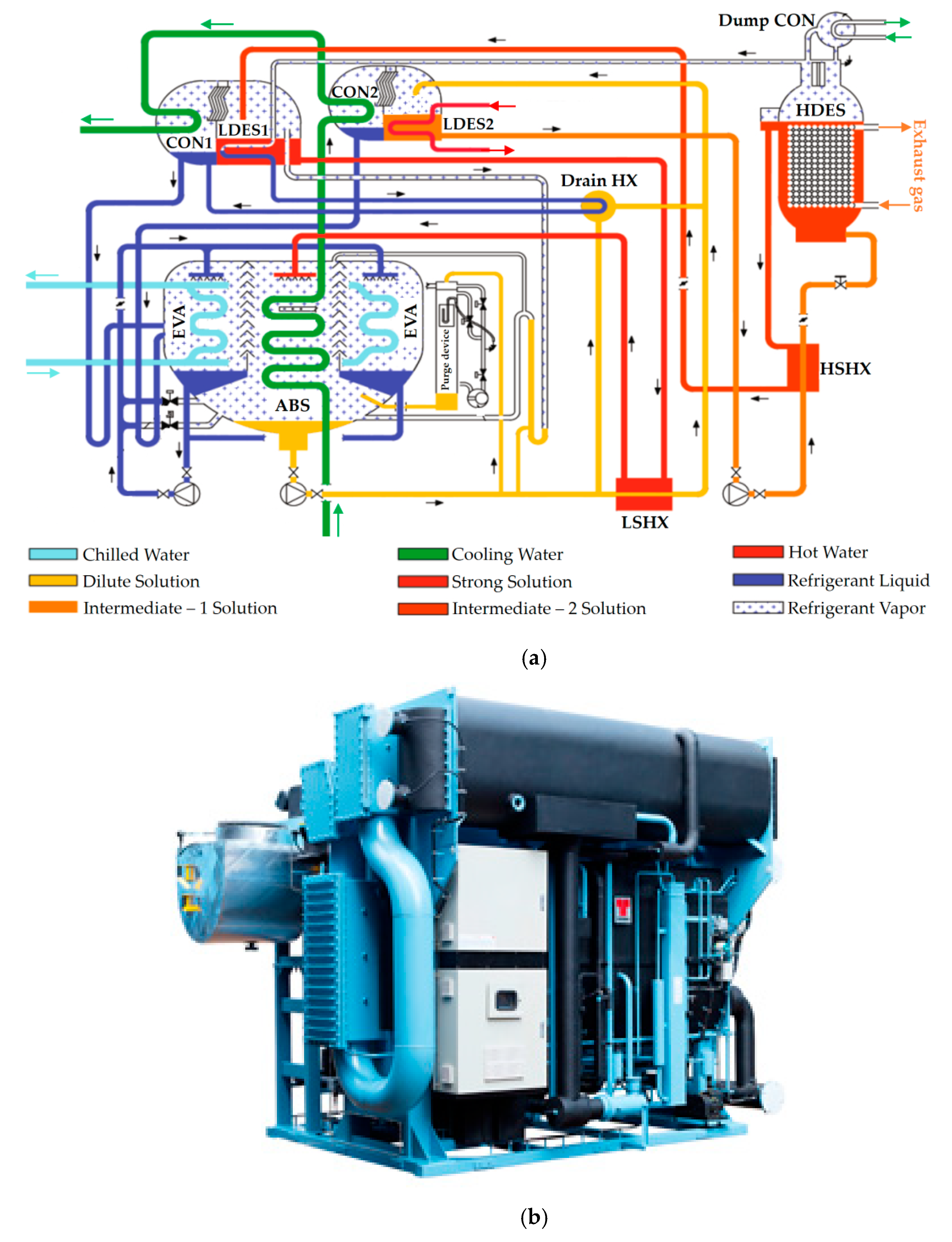

This means that a particular chiller can have its own combination of selected elements. We can model the absorption chiller by considering the energy balance in the four. Heat separates lithium bromide and water.

The history of absorption chillers in north america was to never run a unit test before shipment. Condensing (condenser), expansion (expansion pipe), evaporation (evaporator), absorption. It has an absorption chiller, an absorber, or an absorber, and a generator or heat.

Water steadily evaporates and rises to the condenser, while lithium bromide sinks. The absorption refrigeration cycle is used in both small and large air. Waste heat at high temperatures (95/75°c), heats up the h 2 o/libr mixture.

Generators, condensers, evaporators, and absorbers. Absorption chillers typically require a larger cooling tower compared to a mechanical chiller with the same capacity. In this chamber the water vapour (h 2 o) is separated from the lithium bromide (libr).